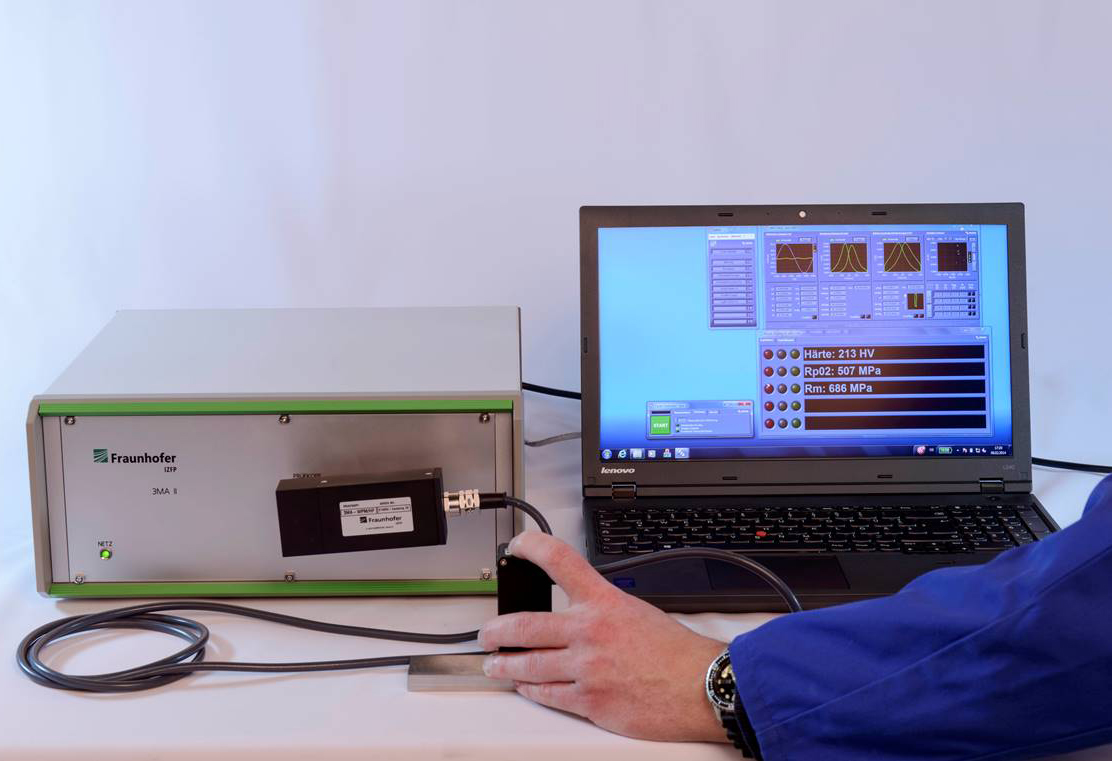

3MA THD inspection system for the micro-magnetic determination of material characteristics and parameters, such as Hardening Depth, CHD/NHD, Hardness, mechnical properties. Non-destructive Testing material properties in manufacturing processes – rapidly, nondestructively and ready for 100 percent inspection.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr LiTransmission components, as well as iron and steel parts used in machines, vehicles and plant engineering are often made from ferromagnetic materials. These components are thermally treated and machined in order to create the desired functional characteristics for use. Determining the quality of the surface layer properties, such as hardening depth, carburized / nitrided layer thickness, hardness profile, requires the application of adequate measurement techniques. Conventional testing methods, viz. metallographic analysis, cross-sectional indention hardness profile, are used to achieve this aim. Inherent to these methods is the slow testing performance and the destructive nature of the testing procedure. Therefore, they are inadequate for in situ inspection of the boundary surface properties, during or shortly after a certain manufacturing stage in the process chain.

|

|

The aforementioned destructive testing methods for characterizing boundary surface layers can be superseded by a modern nondestructive testing procedure named "3MA (Micromagnetic Multiparameter Microstructure and stress Analysis)”NDT measurement technique. The procedure can be performed fully automated and can be integrated into the manufacturing process. Its high inspection speed enables to characterize and analyze materials during or directly after a production step with up to 100 percent.

|

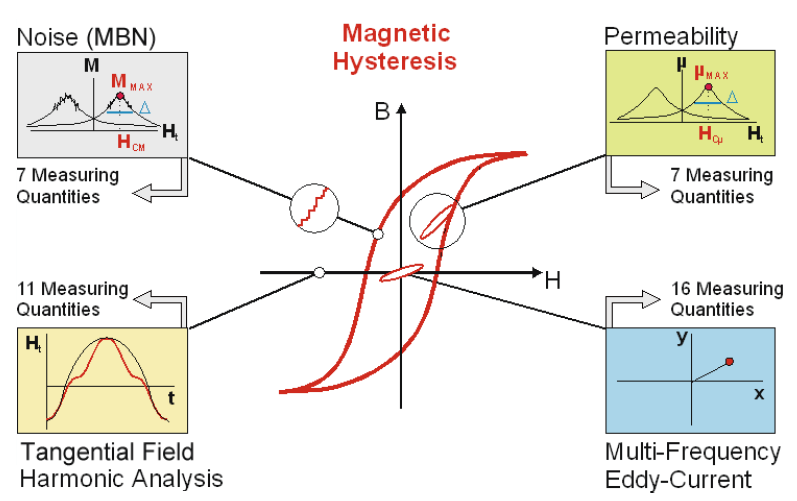

As a combination of hardware and mature process engineering, 3MA comprises four micromagnetic measurement methods: ■ Magnetic Barkhausen noise analysis; ■ Incremental permeability analysis; ■ Harmonic analysis of tangential magnetic field strength; ■ Multi-frequency eddy current analysis. Carrying out these 4 methods under multiple frequencies supplies over 40 micromagnetic parameters which represent the characterization of the material structure. |

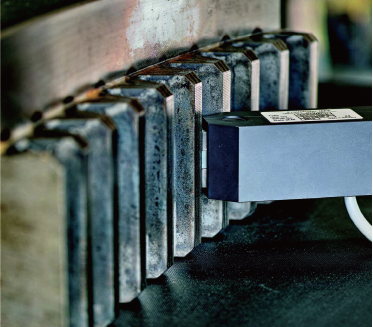

Analyze hardness and depth of IHD/CHD/NHD Analyze hardness and depth of IHD/CHD/NHD |

Steel cable applied and residual stress analysis Steel cable applied and residual stress analysis

|

The 3MA NDT methods allow the fast and concurrent evaluation of several relevant quality characteristics of the material or parts.

Benefits of 3MA THD Nondestructive Measuring:►Fast, non-destructive measuring of material characteristics.►Simultaneous determination of multiple quality parameters. ►Continuous monitoring and documentation of quality parameters. ►Substitutes destructive testing methods. ►More cost-effective production by reducing the costs associated with testing and defects (rejects, rework, etc.). ►Complete and comprehensive integrated process monitoring. ►Custom implementation to meet special requirements (test probe design, software, etc.). |

|

Case Hardening Quality Characterization of Gears Case Hardening Quality Characterization of Gears

|

Special probe for Pistons‘ Hardening depth Special probe for Pistons‘ Hardening depth

|

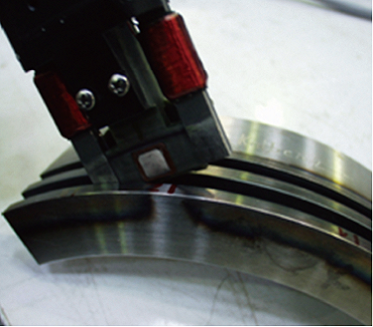

Automated gear wheel scanner Automated gear wheel scanner

|

Hardening depth of Crankshaft Hardening depth of Crankshaft

|

For more details, please contact LAB GAGES directly.

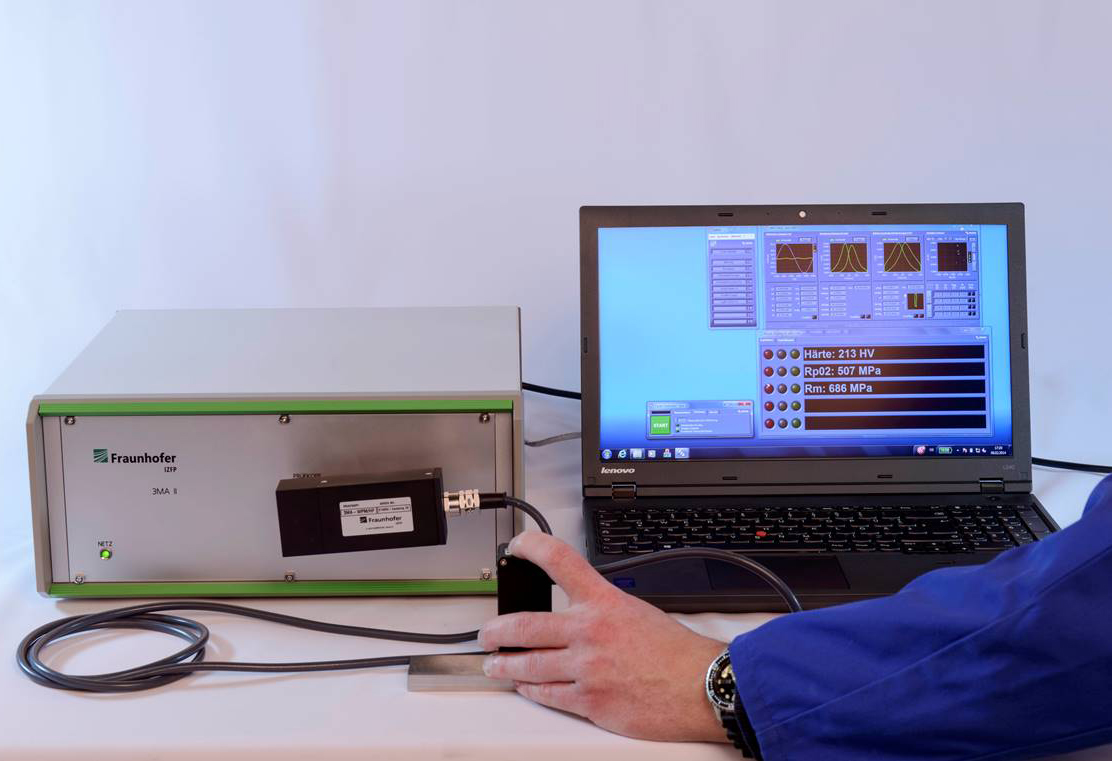

3MA THD Multi-Function Measuring Instrument

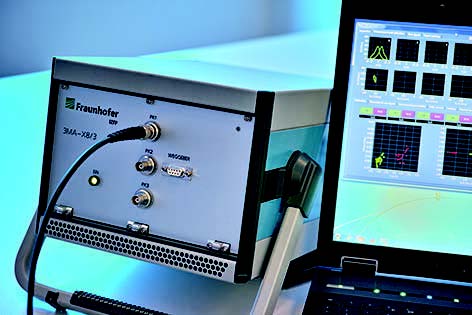

3MA THD Multi-Function Measuring Instrument 3MA-X8 System for Fast Materials Characterization

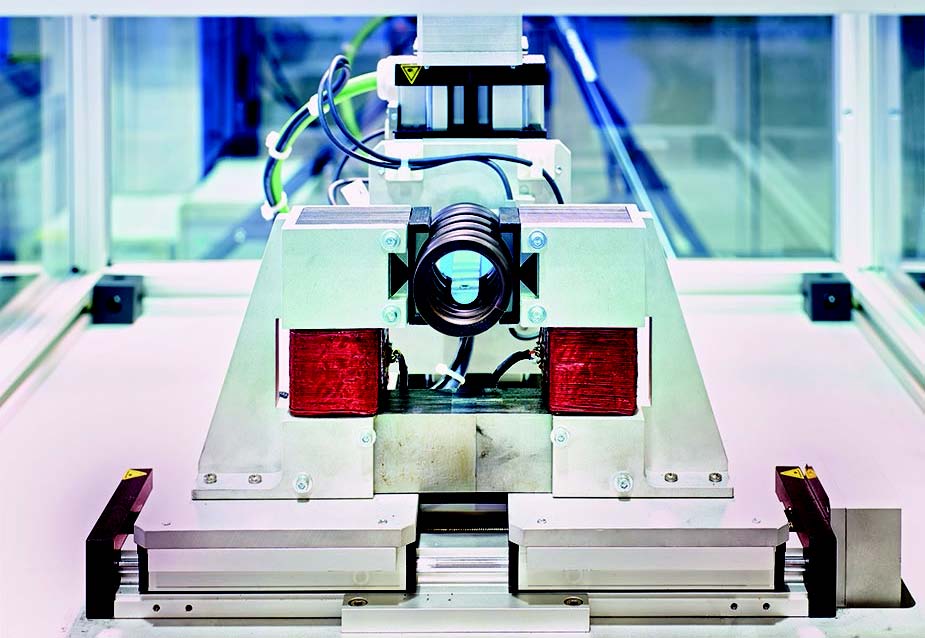

3MA-X8 System for Fast Materials Characterization Hardness & Residual Stress Depth Profiles NDE Scanner

Hardness & Residual Stress Depth Profiles NDE Scanner 3MA Inspection of Press Hardening Parts

3MA Inspection of Press Hardening Parts Barkhausen Noise and Eddy Current Microscope BEMI

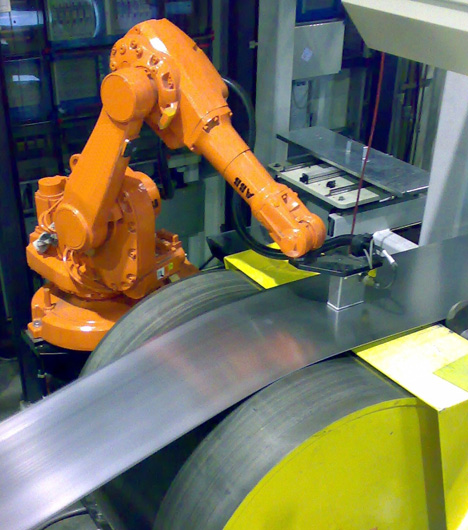

Barkhausen Noise and Eddy Current Microscope BEMI Magnus Hybrid System for In-Line Inspection of Advanced High-Strength Steel

Magnus Hybrid System for In-Line Inspection of Advanced High-Strength Steel 3MA-SOM steel online monitoring system

3MA-SOM steel online monitoring system 3D SmartInspect-Intelligence in Inspection and Quality Control

3D SmartInspect-Intelligence in Inspection and Quality Control

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

沪公网安备 31011502000213号

沪ICP备12021537号-1

©2012-2024 LAB GAGES

沪ICP备12021537号-1

©2012-2024 LAB GAGES