3D SmartInspect is suitable for intelligent inspection monitoring and documentation by optical tracking system for ultrasound and Eddy Current inspection

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr Li

In the case of the widely used manual inspection, the quality of the inspection depends strongly on the personnel and the environmental conditions; this fact concerns the inspection of small components in production as well as the maintenance inspections of large industrial structures. The adequate interpretation of the measured values and the thorough coverage of the inspection area require a high degree of personal expertise. In addition, companies face considerable challenges with regard to documentation. Often, inspection reports are drawn up by hand and any peculiar observations are marked on the components themselves. A digital link between the specimen and the documentation is not established. If inspections take several hours or days, errors and incomplete documentation can occur, leading to negative consequences for subsequent processes.

To solve this topic, Fraunhofer IZFP has developed the optical tracking system "3D SmartInspect", an assistance system for manual inspections based on cognitive signal evaluation.

Fraunhofer IZFP "3D-SmartInspect" technology provides unique options to ensure objective and quantified inspection of large and / or safety-relevant industrial structuress. Parallel to the fully digitized recording of the manual or robot-assisted inspection process by cameras – including tracing of the probe position – all volume data, generated in realtime from the measurement signals, are visualized, optionally via HoloLens, tablet PC, or laptop. The automated generation of a digitized inspection protocol will significantly facilitate processing, analysis, and control of the manual inspection process. Then again, such an extension will substantially relieve the inspectors. In the long term, time-killing and failure-prone preparatory work will be superseded and the degree of the inspectors' individual competence won't influence the inspection reliability any longer. Additionally, engineers can accurately record relevant data with intelligent, assisting sensor systems and gainfully use it in the digital product memory – in every phase of the product lifecycle.

3D SmartInspect – a Fraunhofer IZFP tool for the digital NDT world: Augmented Reality System as a support for the manual inspection of components or large surfaces

One hundred percent inspection: The system itself warrants the thorough scan of the inspection area and the localization of all identified imperfections (e.g., cracks, corrosion).

Reduction of the inspection time: The inspection procedure is speeded up by visualization of areas which are already inspected and areas which have yet to be inspected. Thus, multiple scanning of one and the same area can be avoided.

Digital inspection memory: The automated documentation of the inspection results works as a proof for the reliable realization of the manual inspection in accordance with requirements of quality assurance.

For more details, please contact us.

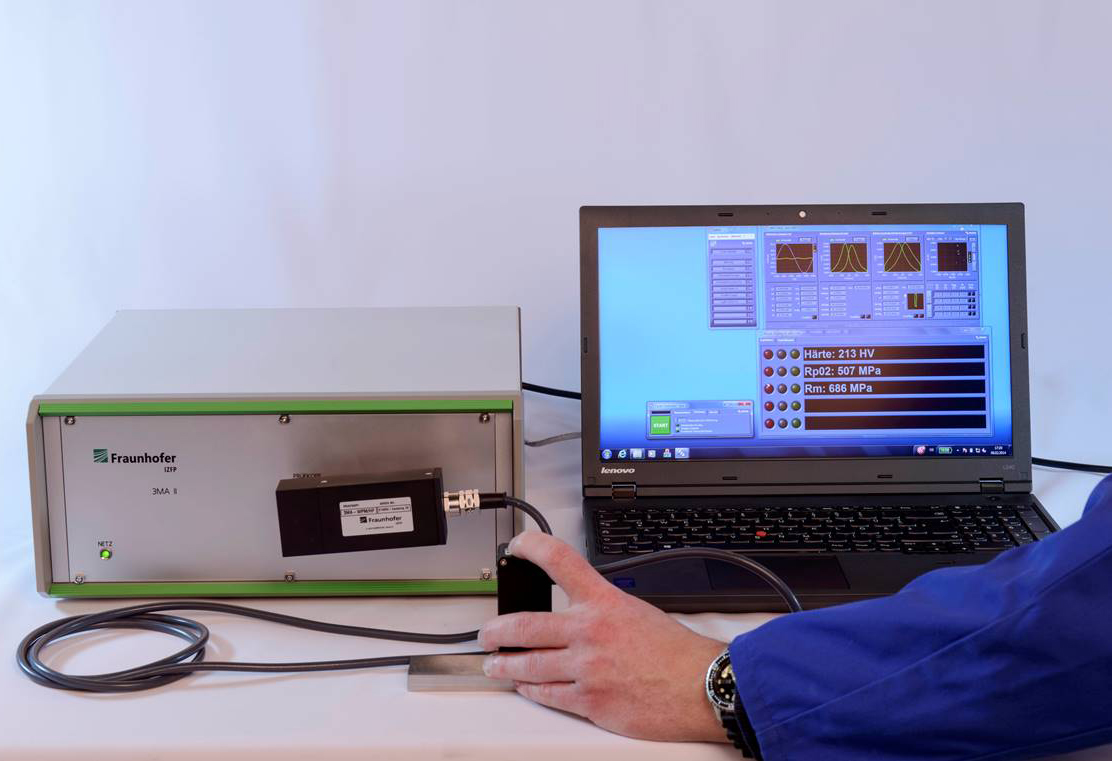

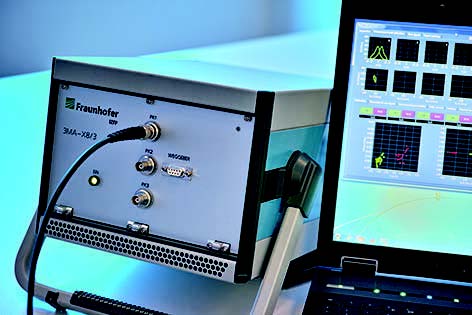

3MA THD Multi-Function Measuring Instrument

3MA THD Multi-Function Measuring Instrument 3MA-X8 System for Fast Materials Characterization

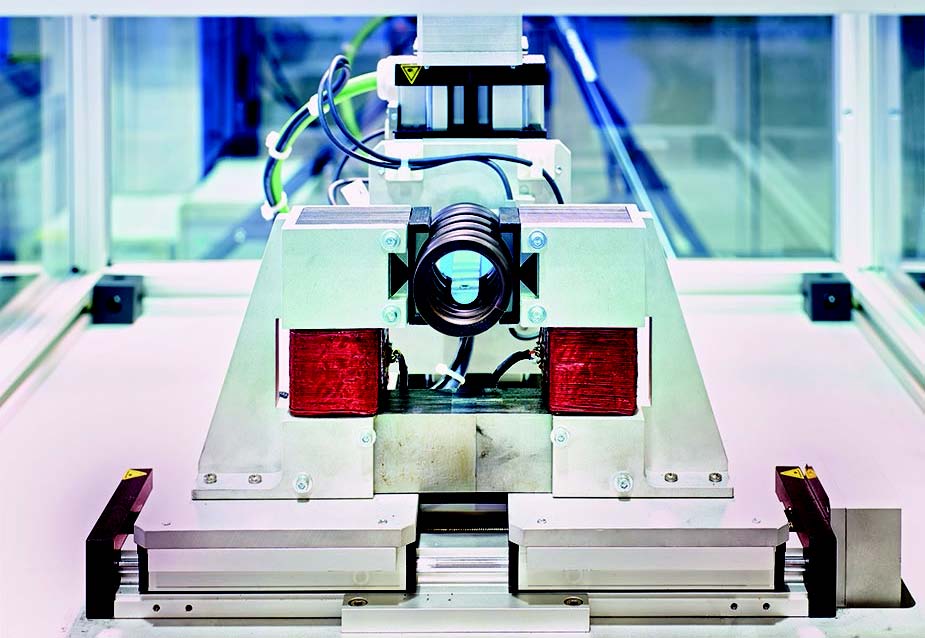

3MA-X8 System for Fast Materials Characterization Hardness & Residual Stress Depth Profiles NDE Scanner

Hardness & Residual Stress Depth Profiles NDE Scanner 3MA Inspection of Press Hardening Parts

3MA Inspection of Press Hardening Parts Barkhausen Noise and Eddy Current Microscope BEMI

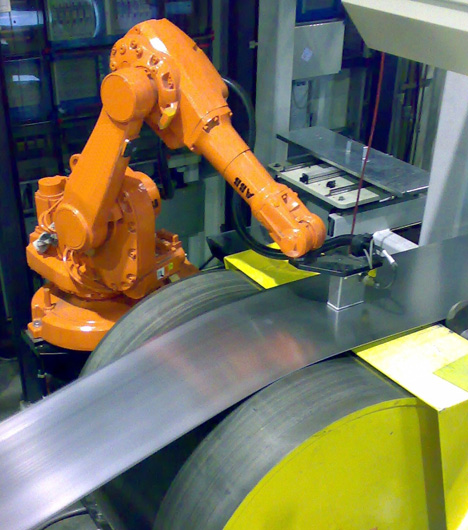

Barkhausen Noise and Eddy Current Microscope BEMI Magnus Hybrid System for In-Line Inspection of Advanced High-Strength Steel

Magnus Hybrid System for In-Line Inspection of Advanced High-Strength Steel 3MA-SOM steel online monitoring system

3MA-SOM steel online monitoring system 3D SmartInspect-Intelligence in Inspection and Quality Control

3D SmartInspect-Intelligence in Inspection and Quality Control

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

沪公网安备 31011502000213号

沪ICP备12021537号-1

©2012-2024 LAB GAGES

沪ICP备12021537号-1

©2012-2024 LAB GAGES