Nondestructive testing (NDT) means the process of examining components and products for quality defects without having to take them apart or destroy them. The Smart NDT applications are now fitting into Industry 4.0, being widened by Cognitive sensor systems, Machine learning and Intelligent monitoring, for the product life cycle, from raw material through usage all the way to recycling.

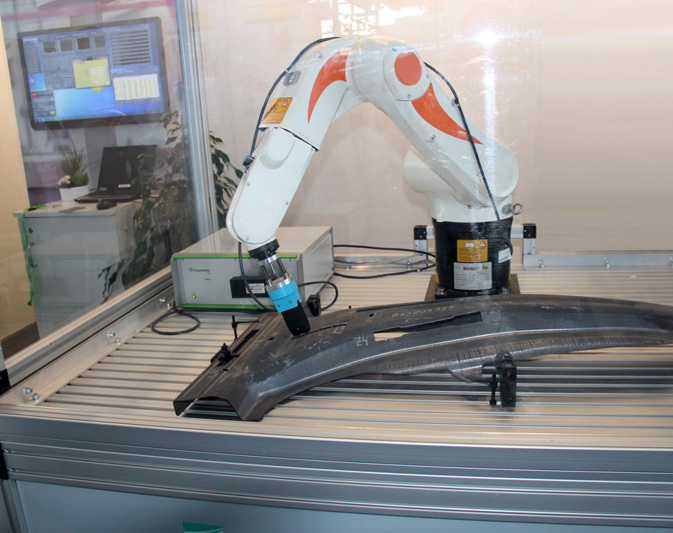

3MA Testing Systems

3MA: Micromagnetic Multiparameter Microstructure and stress Analysis. 3MA inspection technology represents a modern measurement technique for characterizing material properties – rapidly, nondestructively, efficiently and ...

more

Hardening Depth Inspectors

Mobile Testers for nondestructive Inspection of the surface hardening depth in inductively hardened components by IZFP Ultrasound Backscattering Technology - IZFP has more than 30 years of experience with customized ultrasonic hardware and software.

more

CT-Computed Tomography

TomoScope series X-CT (Computed Tomography) composite coordinate measuring machine integrates X-ray scanning imaging technology into the three-coordinate measuring system to realize accurate measurement of non-destructive visualization of products, and can be equipped with various sensors such as optical, optical fiber, contact probe and laser.

more

Thickness Measurement

Thickness gauges are instruments used to measure the thickness of materials and objects. It is commonly used in industrial production to measure the thickness of products (such as steel plates, steel strips, films, paper, metal foils, etc.) continuously or sampled.

more

Flaw Detector

The flaw detector test usually emits ultrasound on the object to be measured (such as industrial materials, human body), and then uses its reflection, Doppler effect, transmission, etc. to obtain information inside the measured object and process it to form an image nondestructively.

more

Ferrite & Conductivity Tester

In chemical machinery, nuclear industry, shipbuilding, boiler manufacturing and other industries, a large number of pressure vessels, pipes, components and valves, etc., are mostly made of austenitic stainless steel and duplex stainless steel. Welding of stainless steel containers loaded with different media requires control of different delta ferrite contents. Electrical conductivity is an important material property that not only provides information about a metal's ability to conduct electrical current, but also provides information on its composition, microstructure, and mechanical properties.

more

Gloss meter

Glossmeter (also gloss meter) is used for measuring specular reflection (gloss) of a surface, to get gloss units of painted, coated and shiny surfaces typically from 20-degree, 60-degree and 85-degree reflective angles.

more

Orange Peel Meter

Orange peel meter scans the optical profile of high gloss surfaces using a laser light source, and objectively evaluate Orange Peel and DOI on very curved components or small add-on parts - like fuel doors, mirror housings, door handles, decorative trim or motorcycle parts, for medium to high gloss finishes.

more

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

沪公网安备 31011502000213号

沪ICP备12021537号-1

©2012-2024 LAB GAGES

沪ICP备12021537号-1

©2012-2024 LAB GAGES