Fraunhofer Barkhausen Noise and Eddy Current Microscope BEMI is used for micromagnetic nondestructive inspection of metallic materials and layered systems with high spatial resolution

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr Li

Knowledge of material properties and their local distribution is of great importance for the development and optimization of metallic materials or layered systems. The application of the multiparameter

micromagnetic testing method BEMI provides the capability to characterize the material properties or layered systems with high spatial resolution.

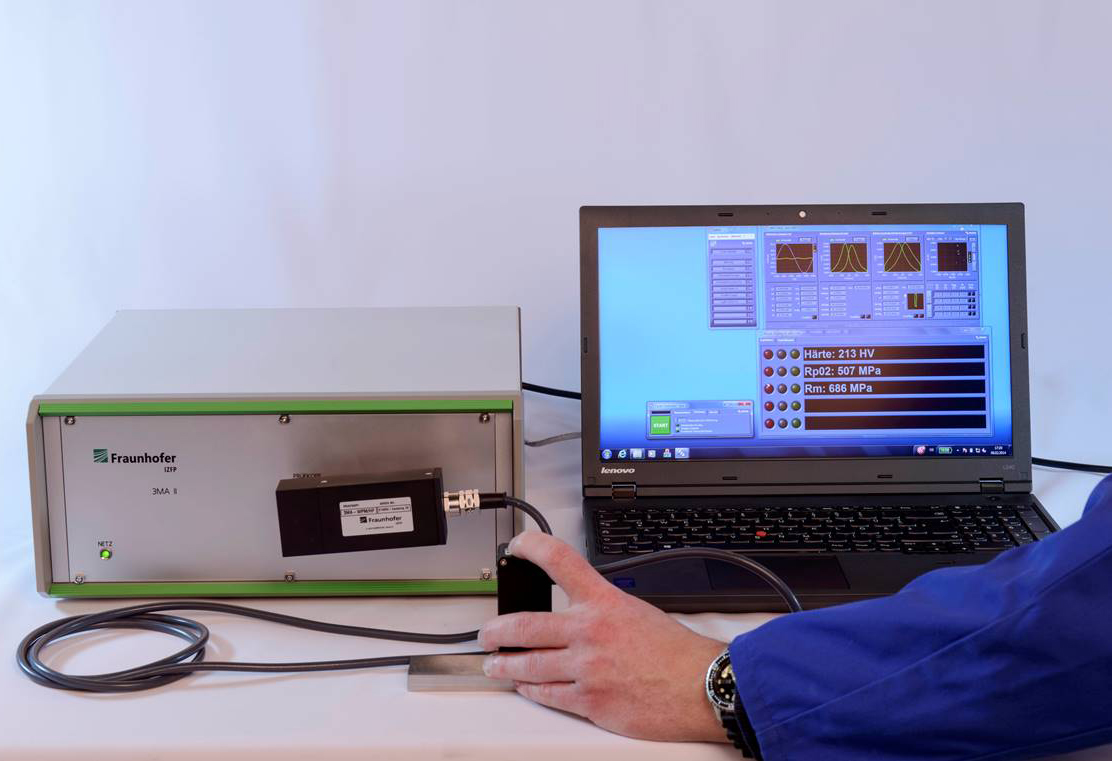

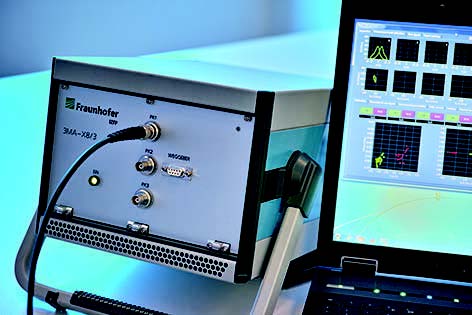

■ Inspection main device based on 3MA technique (3MA: Micromagnetic Multiparameter Microstructure and Stress Analysis): A powerful testing device for micromagnetic characterization of materials and layered systems;

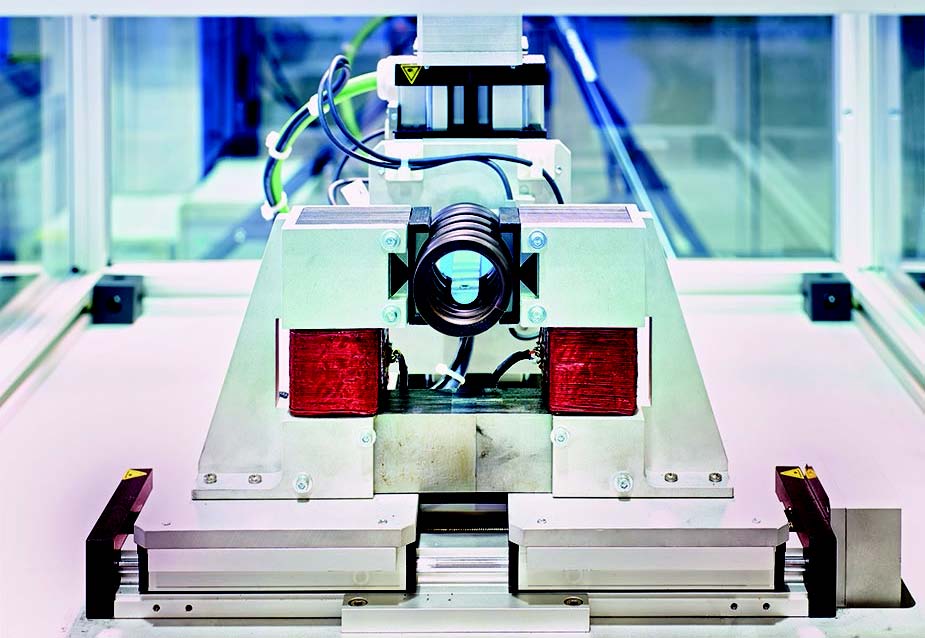

■ Special probe with high spatial resolution: Acquisition of electromagnetic properties with a spatial resolution of about 20 μm;

■ Scanning machine: Stepwise scanning of sample surfaces in defi ned X and Y positions;

■ Computer: Control of the scanner, acquisition of data, visualization of the results and evaluation;

The Inspection main device based on 3MA technique, combines the four micromagnetic methods: Harmonic analysis of the tangential magnetic fi eld strength, Barkhausen noise signal analysis, Incremental permeability analysis, Multi-frequency eddy current impedance analysis.

The application of these methods with several testing frequencies provides more than forty micromagnetic characteristics, which correlate to the properties of the material structure and layered systems. The combination of the micromagnetic characteristics in a multiparameter approach enables the separation of overlapped infl uences, for example stress and layer thickness. The image of the distribution of these micromagnetic characteristics provides primary information on material homogeneity. Furthermore, the comparison of the characteristics of several samples allows for a qualitative estimation of the differences in material or layer properties.

|

|

|

Above all, after a single calibration using samples with defined characteristics, BEMI can determine material and layer properties quantitatively and show their distribution as an image. It is possible to determine several target values simultaneously.

► Materials characterization and optimization with high spatial resolution for all materials or layered systems containing at least one metallic component.

► Examination of the homogeneity of microstructure or layers.

► Imaging of stress distribution.

► Determination of the thickness of a metallic and/or ferromagnetic top layer on any substrate.

► Determination of the thickness of a non-ferromagnetic top layer on a ferromagnetic substrate.

► Characterization of multilayers.

For more details, please contact LAB GAGES directly.

3MA THD Multi-Function Measuring Instrument

3MA THD Multi-Function Measuring Instrument 3MA-X8 System for Fast Materials Characterization

3MA-X8 System for Fast Materials Characterization Hardness & Residual Stress Depth Profiles NDE Scanner

Hardness & Residual Stress Depth Profiles NDE Scanner 3MA Inspection of Press Hardening Parts

3MA Inspection of Press Hardening Parts Barkhausen Noise and Eddy Current Microscope BEMI

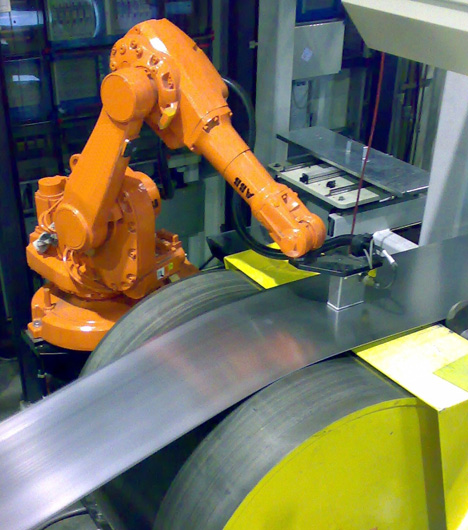

Barkhausen Noise and Eddy Current Microscope BEMI Magnus Hybrid System for In-Line Inspection of Advanced High-Strength Steel

Magnus Hybrid System for In-Line Inspection of Advanced High-Strength Steel 3MA-SOM steel online monitoring system

3MA-SOM steel online monitoring system 3D SmartInspect-Intelligence in Inspection and Quality Control

3D SmartInspect-Intelligence in Inspection and Quality Control

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

沪公网安备 31011502000213号

沪ICP备12021537号-1

©2012-2024 LAB GAGES

沪ICP备12021537号-1

©2012-2024 LAB GAGES