FMP20 flexiblely uses magnetic induction (Delta), eddy current method (Iso) or both methods (Dual), non-destructive and high-precision measurement of coating. Fischer FMP20 magnetic induction coating thickness gauge is advanced, durable and user-friendly, with interchangeable probes for a wide range of measurement applications.

Inquiry Online Sales Manager: Mr Li

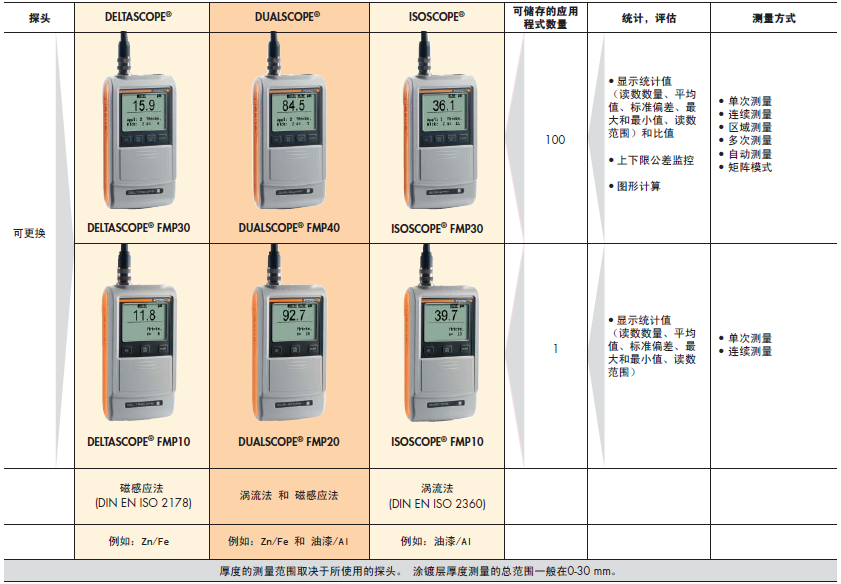

Sales Manager: Mr LiThanks to its modular design, you can choose instruments and probes for your specific needs. For the instrument, you can choose from the new FMP family (see the table below) according to your application; for the probe, we provide you with a large number of high-precision probes, I believe there must be one for you.

You will definitely find the right instrument for you from the new FMP family. The main criteria for selecting an instrument are the type of coating and the material of the substrate, and then decide whether you want a basic instrument (FMP10/FMP20), or have extended application memory, a lot of graphics and statistics. Model with calculation function and various measurement options (FMP30/FMP40).

|

• The thickness of the coating is measured non-destructively according to the magnetic induction method and/or the eddy current method. • Automatic identification of probes and substrates. • Rugged housing and high contrast large size graphic display. • The instrument is easy to operate and has a variety of statistical evaluation capabilities. • The USB interface can be connected to a computer, and the FMP30-40 can also be connected to a printer. • Innovative probe technology makes measurements more accurate and has a wider measurement range. |

|

|

✍Can be used with all probes based on magnetic induction and eddy current methods ✍ Automatic identification probe ✍ Automatic identification of substrates (FMP20) ✍ Instrument operation interface is friendly ✍ USB interface can be connected to a computer ✍Large display with 240x160 pixels high contrast ✍ Can be measured after power on • Insert probe to measure ✍ Sound prompt after measurement is completed ✍ Adapt to substrate shape (normalized) with simple zero correction ✍ Easy to calibrate (using one or two foils) ✍ Set the main calibration mode for products with rare materials or complex shapes (need to be used with the main calibration standard) ✍ Can adjust the instrument automatic shutdown time and continuous use time ✍ Instrument status display (for example: warning message when battery is low) ✍ Keypad lock/function limit mode ✍ Slide protection keyboard ✍ Multi-language display ✍The unit of measurement can be switched between μm and mils |

The quality of a measurement is primarily determined by several key factors. Including: selecting the appropriate probe and the quality of the probe itself. Helmut Fischer GmbH offers a wide range of high-precision probes of all quality, all of which are developed and produced to their own high quality.

The type of coating/substrate is an important basis for selecting a probe. In addition, the approximate thickness of the plating, the material of the substrate, the area of the measuring point, and the shape and surface condition of the sample are all factors to consider when selecting the probe. The curvature compensation probe (eddy current method) is suitable for samples with different surfaces; the double contact probe provides accurate results on rough surfaces. FMP1, FMP20, FMP30, and FMP40 instruments can be connected to different probes to meet your different measurement needs.

Germany Fischer coating thickness gauge Dualscope MP0

Germany Fischer coating thickness gauge Dualscope MP0 DeltaScope FMP30 Coating thickness Gauge

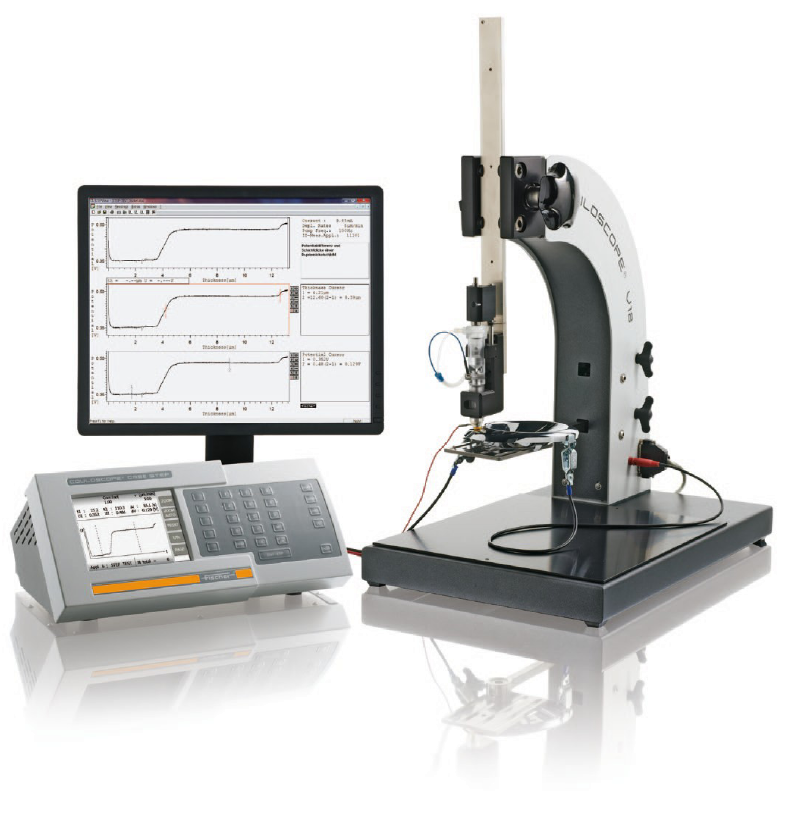

DeltaScope FMP30 Coating thickness Gauge COULOSCOPE CMS2 multi-coating thickness Instrument

COULOSCOPE CMS2 multi-coating thickness Instrument FMP10 Handheld Coating Thickness Gauge

FMP10 Handheld Coating Thickness Gauge Fischer FMP20 magnetic induction coating thickness gauge

Fischer FMP20 magnetic induction coating thickness gauge EPK MiniTest 7400FH wall thickness measurement gauge

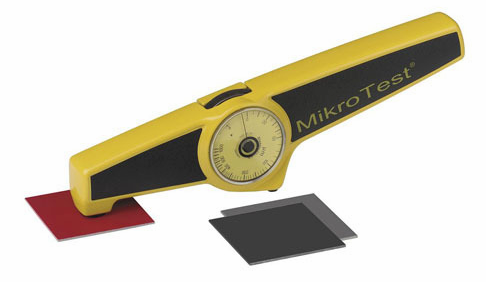

EPK MiniTest 7400FH wall thickness measurement gauge Mechanical coating thickness gauge: MikroTest

Mechanical coating thickness gauge: MikroTest SmartTest Smart Wireless Film Thickness Sensor

SmartTest Smart Wireless Film Thickness Sensor Multi-coat Ultrasonic Thickness Gauge QuintSonic

Multi-coat Ultrasonic Thickness Gauge QuintSonic MiniTest 725/735/745 Digital Coating Thickness Gauge

MiniTest 725/735/745 Digital Coating Thickness Gauge

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

沪公网安备 31011502000213号

沪ICP备12021537号-1

©2012-2024 LAB GAGES

沪ICP备12021537号-1

©2012-2024 LAB GAGES