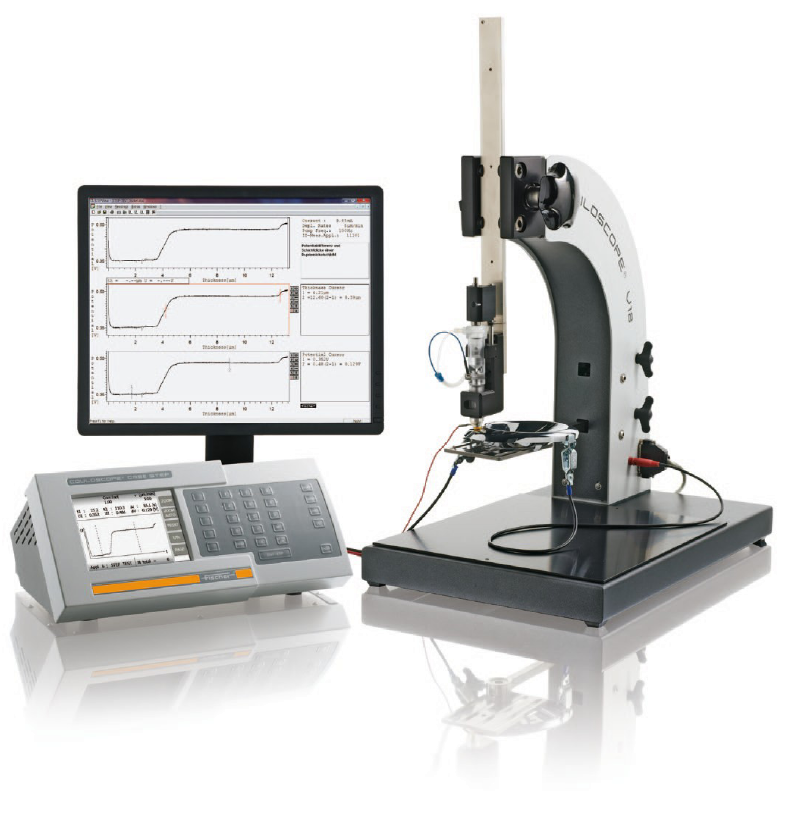

QuintSonic uses advanced ultrasonic sensing technology and innovative software to achieve high-precision simultaneous measurement of up to 5 coatings. Suitable for paint, enamel and plastic coatings on plastic, metal, wood, ceramic, glass substrates.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr LiThis innovative technology is through the A-scan image function. You can display chart information directly without connecting the instrument to a computer. As a result, the reliability of measurement under any circumstances is greatly realized, making QuintSonic 7 an ideal tool for field, laboratory or workshop measurement. QuintSonic 7 is widely used in all industries that require high-precision measurement, such as in the automotive industry and handicraft industry.

|

QuintSonic 7 Another feature: Thin substrate thickness can be measured through coating |

|

|

Working Principle: Based on ultrasonic reflection, after the ultrasonic pulses emitted by the Quint Sonic 7 smart probe enter the coating, when the pulses are transmitted to the bonding surface of the coating or the critical surface of the substrate, some of the pulses are reflected back. These reflected ultrasonic pulses are received by the sensor, and the thickness of the coating is calculated from the speed of sound waves traveling through the medium. |

|

|

QuintSonic 7's outstanding features: The instrument uses very advanced sensing technology and innovative software to achieve high-precision measurement during application, which could not be achieved before. QSoft software can display A-scan image during measurement, which can get more accurate data. Parameter settings are used to define the measurement range, anti-interference, echo diagnosis and estimated cut-off band range. The cut-off band can be set to eliminate clutter, such as clutter caused by the substrate GRP or CRP fiber. Another difficulty with ultrasonic coating thickness measurement is the measurement of coating thickness with similar characteristics. The difference in the impedance values of these coatings is not sufficient to distinguish the feedback ultrasonic pulses. QuintSonic 7 solves this problem through technological innovation. Weak pulse signals can be clearly distinguished. Therefore, complex measurement tasks can be completed reliably and accurately. A new feature of the instrument is that the speed of sound of standard samples can be built into the instrument. Once the sound velocity of a certain medium is determined, the sound velocity can be stored in a database for retrieval. This reduces setup time during measurement. |

|

|

Standard accessories |

Optional accessories |

|

● QuintSonic 7 host ● Probe ● Carrying case ● CD with operating instructions ● 2 x 100 ml couplant (glue / oil) ● One-layer reference sample ● USB data cable ● 4 x AA batteries |

● MiniPrint 7000 printer ● NiMH Ni-MH battery fast charging device ● External power supply ● Shoulder strap ● Positionable rubber protective sleeve and shoulder strap ● Multi-purpose junction box with USB cable, connect external power supply, foot switch, alarm, earphone ● QSoft professional data management software ● IrDA / USB converter |

Germany Fischer coating thickness gauge Dualscope MP0

Germany Fischer coating thickness gauge Dualscope MP0 DeltaScope FMP30 Coating thickness Gauge

DeltaScope FMP30 Coating thickness Gauge COULOSCOPE CMS2 multi-coating thickness Instrument

COULOSCOPE CMS2 multi-coating thickness Instrument FMP10 Handheld Coating Thickness Gauge

FMP10 Handheld Coating Thickness Gauge Fischer FMP20 magnetic induction coating thickness gauge

Fischer FMP20 magnetic induction coating thickness gauge EPK MiniTest 7400FH wall thickness measurement gauge

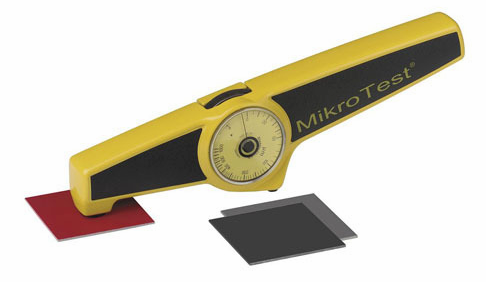

EPK MiniTest 7400FH wall thickness measurement gauge Mechanical coating thickness gauge: MikroTest

Mechanical coating thickness gauge: MikroTest SmartTest Smart Wireless Film Thickness Sensor

SmartTest Smart Wireless Film Thickness Sensor Multi-coat Ultrasonic Thickness Gauge QuintSonic

Multi-coat Ultrasonic Thickness Gauge QuintSonic MiniTest 725/735/745 Digital Coating Thickness Gauge

MiniTest 725/735/745 Digital Coating Thickness Gauge

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

沪公网安备 31011502000213号

沪ICP备12021537号-1

©2012-2024 LAB GAGES

沪ICP备12021537号-1

©2012-2024 LAB GAGES