SmarTest's SIDSP smart sensor for measuring coating thickness combines the advantages of modern wireless technology with excellent accuracy against interference. The sensor data is transmitted to the tablet, smartphone app or coating thickness gauge MiniTest 745 via Bluetooth.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr Li

|

● Precision coating thickness gauge with digital probe ● Can connect any SIDSP probe ● Transmission of measurement data via Bluetooth, with a range of about 10 meters ● Currently displayed and operated in 4 languages (German, English, French, Chinese) through the app ● Wear-resistant probe with almost unlimited life ● Very suitable temperature compensation through separate compensation characteristic curve ● High precision characteristic curve of up to 50 points in the manufacturer's calibration ● Rechargeable battery for more than 8 hours of operation ● The battery is charged using the mini USB socket ● Built-in battery control prevents incorrect measurements due to low battery power ● Store and transmit measurement data in CSV format |

|

● The app is used to evaluate various measurement data and store and transfer it as a CSV file. ● High-capacity battery with power alarm display, continuous operation for about 8 hours ● Application can be updated automatically |

|

|

Operating The operation of SmarTest is very simple: ➤ Launch the SmarTest app on your mobile device ➤ Turn on the wireless adapter and automatically establish a Bluetooth connection ➤ Take a measurement The SmarTest app provides assistance at every step through context-sensitive help texts, currently available in 4 languages. |

|

|

|

Measurement mode There are two measurement modes to choose from: ❏ Single Value Mode Acquire and display measured values separately. This enables you to obtain coating thickness values at multiple points of the object to be measured and then evaluate them statistically. ❏ Continuous Mode After the probe is placed, the measured value is continuously acquired and displayed. This mode is suitable for calculating the coating thickness distribution on a defined surface and positioning thin and thick parts. Measured values calculated in continuous mode can be saved in the statistics by briefly pressing the power button. |

|

|

|

Control / data transfer Controlling the adapter and transmitting measured value data via Bluetooth 4.0 / Bluetooth Smart (low energy consumption). The distance between the adapter and the mobile device can be placed at about 10 meters, and it can be even longer under good transmission conditions. |

|

|

|

App application features The SmarTest app displays current measurements, statistical evaluations, and helps control storage and calibration of probes. There is a choice of metric (μm, mm) and imperial (mils) formats for displaying and processing measurement values. Storage and transmission / downloading of measured values is done in CSV format. |

|

|

|

Calibration Three calibration modes are available: ☑ Factory calibration ☑ 1-point calibration (zero-point calibration) on uncoated workpieces ☑ 2-point calibration (zero-point calibration + 1-point thickness layer / substrate) |

|

|

Application Non-destructive coating thickness measurement: ▶ Non-magnetic coatings on ferromagnetic substrates (e.g. steel) such as varnish, enamel, chromium, zinc ▶ Insulating coatings on non-ferrous metals (e.g. aluminum, austenitic stainless steel, brass) such as varnishes and anodized aluminum |

|

The standard configuration ● SmarTest host with F 2.6 or FN 2.6 probe ● Calibration kit includes calibration plate and reference zero plate ● USB charger and mini USB cable ● Operation manual ● Manufacturer certificate ● Storage box |

Germany Fischer coating thickness gauge Dualscope MP0

Germany Fischer coating thickness gauge Dualscope MP0 DeltaScope FMP30 Coating thickness Gauge

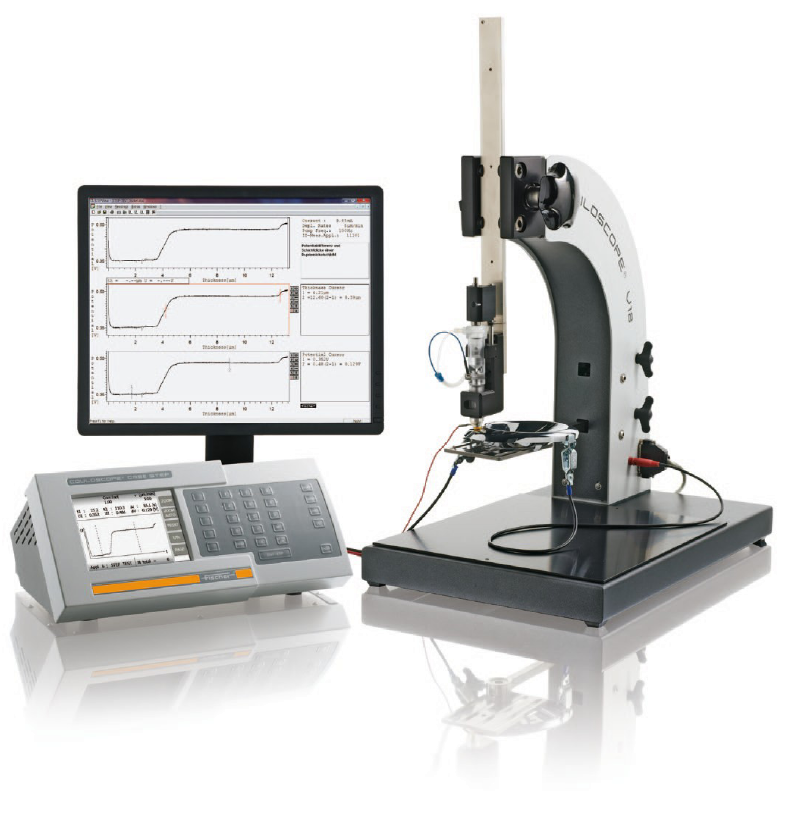

DeltaScope FMP30 Coating thickness Gauge COULOSCOPE CMS2 multi-coating thickness Instrument

COULOSCOPE CMS2 multi-coating thickness Instrument FMP10 Handheld Coating Thickness Gauge

FMP10 Handheld Coating Thickness Gauge Fischer FMP20 magnetic induction coating thickness gauge

Fischer FMP20 magnetic induction coating thickness gauge EPK MiniTest 7400FH wall thickness measurement gauge

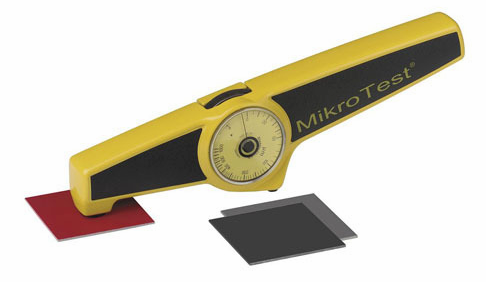

EPK MiniTest 7400FH wall thickness measurement gauge Mechanical coating thickness gauge: MikroTest

Mechanical coating thickness gauge: MikroTest SmartTest Smart Wireless Film Thickness Sensor

SmartTest Smart Wireless Film Thickness Sensor Multi-coat Ultrasonic Thickness Gauge QuintSonic

Multi-coat Ultrasonic Thickness Gauge QuintSonic MiniTest 725/735/745 Digital Coating Thickness Gauge

MiniTest 725/735/745 Digital Coating Thickness Gauge

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

沪公网安备 31011502000213号

沪ICP备12021537号-1

©2012-2024 LAB GAGES

沪ICP备12021537号-1

©2012-2024 LAB GAGES