The 71 Series is a cost-effective portable measuring machine available in both 2.5 and 3.5 meter ranges. With a precision of 50 microns and a weight of only 7.9 kilograms, and compatible with all major metrology software, it is an application-wide, flexible field measurement tool that provides a new metrology solution for a wider range of industries.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr Li

|

Hexagon offers a comprehensive range of products and services for industrial metrology, with customers in the automotive, aerospace, energy and medical sectors. From product development and design to processing, assembly and final acceptance, Hexagon provides users with operational measurement information throughout the product life cycle. |

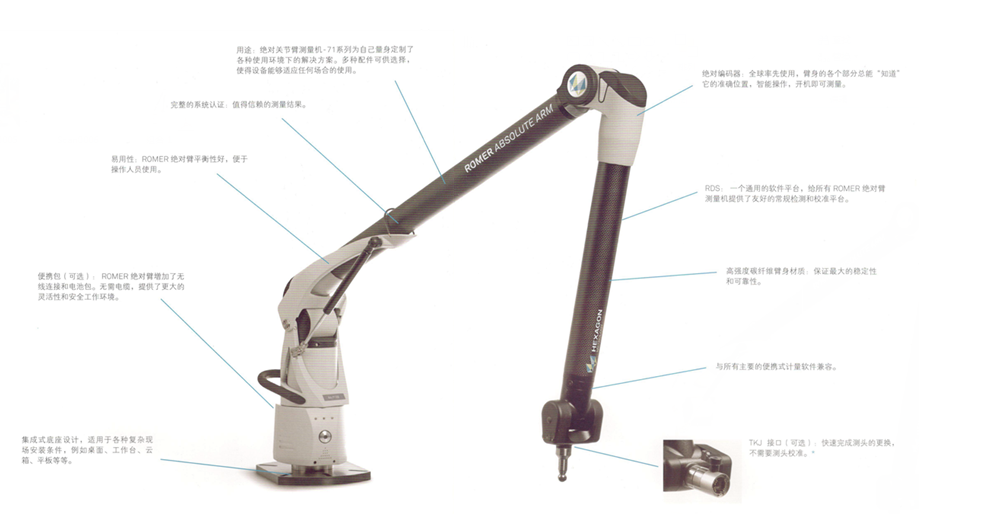

ROMER ABSOLUTE ARM 71 SERIES--Absolute Joint Arm Measuring Machine--71 Series

The 71 Series is a cost-effective portable measuring machine available in both 2.5 and 3.5 meter ranges. With a precision of 50 microns and a weight of only 7.9 kilograms, and compatible with all major metrology software, it is an application-wide, flexible field measurement tool that provides a new metrology solution for a wider range of industries.

|

Technical Parameters |

|

|

|

|

|

Model |

Measuring range |

*Point repeatability |

*Space length accuracy |

Weight |

|

7025 |

2.5m |

0.050mm |

0.069mm |

7.9kg |

|

7135 |

3.5m |

0.103mm |

0.141mm |

8.3kg |

|

*Spot repeatability This series is a reference test for determining the repeatability of an articulated arm measuring machine with a ball probe. The cone is placed in front of the machine, and the articulated arm measures from multiple directions. The deviation from each measurement point to the average measurement center is calculated. The result is the maximum deviation of /2. *Space length accuracy Typical test method for spatial accuracy. Within the measurement range, a standard length standard is measured multiple times. The standard is placed at different positions and measured from different universal directions. The result is the maximum deviation between the actual measured length and the nominal length of the calibration. |

||||

|

Typical Application |

|

|

College and university The Absolute Arm Measuring Machine-71 series opens the door for three-coordinate applications for colleges and universities. It is cost-effective, high-precision, portable and easy to use, especially for the machining process, in the wind tunnel experiment or in the restoration of cultural relics. The detection of the workpiece, the advantage of the ROMER absolute arm is very prominent. The Absolute Arm Measuring Machine Series 71 offers more possibilities for improving students' practical skills. |

Car: Application for ride comfort (NVH) The absolute articulated arm measuring machine 71 series can be conveniently used in a confined space inside the motor vehicle. It can be installed in the car body and can be measured by turning on the power. No other measuring device can perform such a versatile test of the vehicle's feet or pillars. |

|

Agricultural machinery, automobiles, motorcycles: aftermarket accessories Reverse Engineering without Laser Scanning: The Absolute Arm Measuring Machine-71 Series can use contact probes to digitize the relevant parts of the vehicle. The articulated arm can be measured in very difficult to reach spaces, such as the bottom of the car, engine brackets and interior trim, and even the top of some scaffolding. |

Car crash test Infinite portability makes it very easy to measure hard spots around the car and compare the impact of collision experiments on the interior and exterior of the car. The Absolute Arm Measurement System 71 series is also suitable for measuring virtual settings and H points before collision. |

|

Castings and forgings The stable ROMER absolute arm can be used even under harsh environmental conditions. It is especially suitable for measuring billets and ingots before finishing on-site. |

Benchmarking management The rapid acquisition of 3D data allows users to understand the characteristics of their competitors' competitive products in a very short period of time. |

|

Consumer products The trend in design is to move to more complex three-dimensional shapes; This makes traditional measurements more difficult. From home appliances to children's seats and toys, the Absolute Arm Measurements 71 series can be easily measured, saving time and money in product manufacturing. |

Sporting goods Whether it's a jet ski bag or a snowboard bag, the slight shape variations that occur during the manufacturing process can affect the handling. The ROMER absolute arm helps to quickly determine similar problems. |

|

Large household appliances The large measuring range makes it easy to measure the external surface of any household appliance. Flexibility and absolute encoder make it as easy to measure the interior of large appliances. |

Furniture industry The ROMER absolute arm requires only one setup to complete all measurements of the workpiece, including to very difficult to reach. |

|

Inspection of large plastic and rubber parts The 3.5 meter range provides sufficient flexibility for measuring large workpieces. The full leapfrog function allows for the measurement of larger parts. |

Package Design When it comes to providing a package designed for a given product, point digitization is still the way to get accurate 3D CAD data. |

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

沪公网安备 31011502000213号

沪ICP备12021537号-1

©2012-2024 LAB GAGES

沪ICP备12021537号-1

©2012-2024 LAB GAGES