API XD laser interferometer can measure six parameters including positioning accuracy, repeat positioning accuracy, straightness and angle. For the calibration and calibration of CNC machine tools and three-coordinate measuring machines. The test usually takes several days to perform, and it only takes a few hours to use the API laser interferometer. Practical application results show that time can be saved up to 80%.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr Li

Accurate data collectionReal-time error measurement ensures the correctness of data collection and high-precision error analysis; automatic data collection technology simplifies the data collection process. Instrument traceabilityAll parameters (linearity, straightness, angle) of API company XD series laser interferometer are traced to national and international standards. These precisions have been tested by the National Institute of Standards (NIST), China Institute of Metrology, and German PTB. |

|

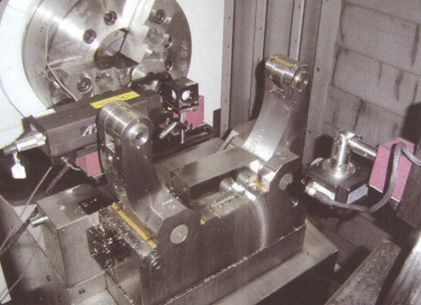

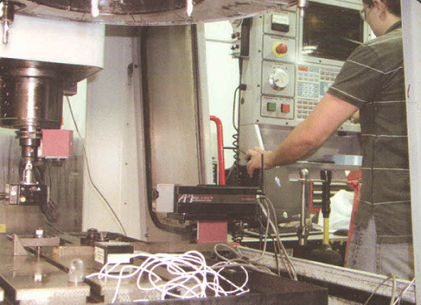

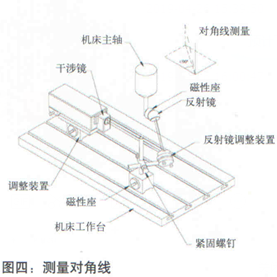

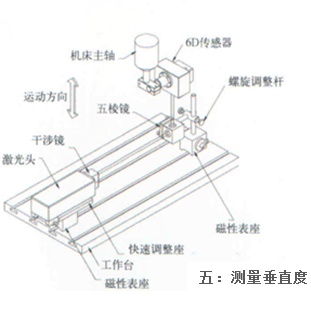

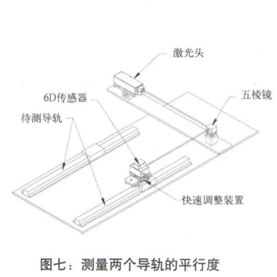

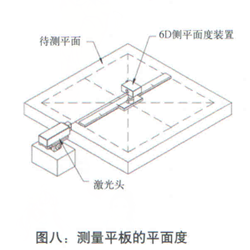

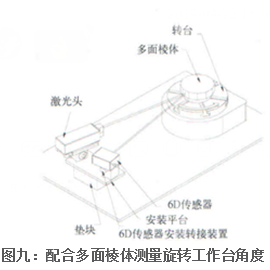

Continuous production and zero-fault scenariosIn order to avoid sudden shutdowns and production stops, API companies provide a complete measurement solution for modern machining shops, which is a zero-fault solution.For a long time, workshop managers have been using 1D laser measurement systems to draw machine tool error maps and perform calibration. So if you want to measure the complete 21 parameters, you need to perform 21 to 24 separate installation and debugging, and each measurement of each axis takes 1-2 hours, so the measurement process of the entire machine usually takes two to three Within one working day, this caused the machine to be stopped for a long time, which seriously affected the profitability and production capacity of the workshop. Using the API company XD Laser laser interferometer completely avoids the above defects, making the measurement of the machine tool fast and simple. |

|

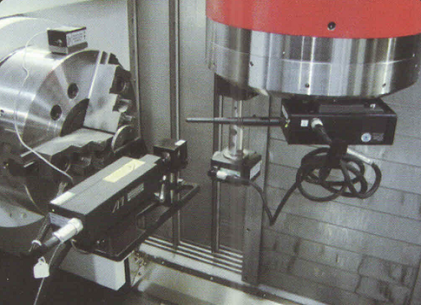

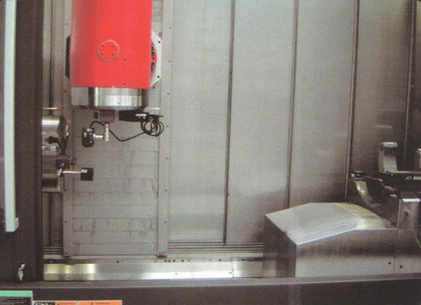

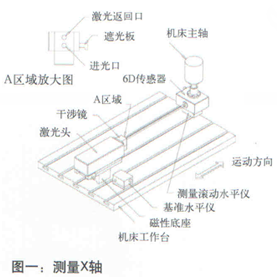

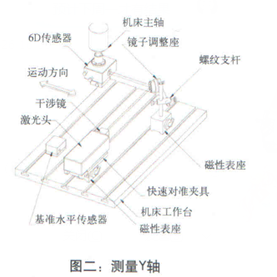

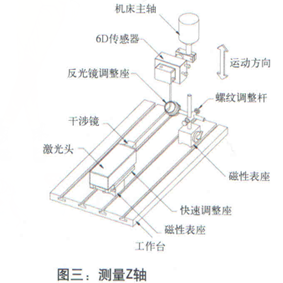

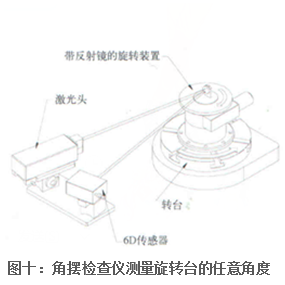

Composition of XD Laser interferometerXD Laser interferometer is improved on the basis of LMS laser interferometer. Integrate the control box into the laser and change the original wired data transmission to wireless data transmission. Therefore, the XD Laser interferometer is composed of a laser head, a sensor, a weather station, a notebook computer and a cable connecting the entire system. |

|

Easy to carry and operateThe complete system weighs only 15 kg and can fit into a small tool box. Due to its compact design, the XD Laser is small and does not require a tripod when measuring machine tools. The measurement datum is consistent with the machining datum of the machine tool, and the measurement procedure is simplified (no need to remove the machine cover). The integrated interferometer and laser are integrated, which simplifies the adjustment steps, reduces the adjustment time, and improves the efficiency of the machine tool. |

|

|

|

|

|

|

|

|

|

|

|

|

▶ 6 parameters can be measured in one installation ▶ Wireless communication system ▶ Highly integrated design for unparalleled portability |

▶ Ethernet connection ▶ Automatic real-time ambient temperature compensation ▶ Built-in humidity sensor |

▶ Real-time data display ▶ Quick installation and commissioning ▶ Compact laser head design |

XD laser interferometer

XD laser interferometer

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

沪公网安备 31011502000213号

沪ICP备12021537号-1

©2012-2024 LAB GAGES

沪ICP备12021537号-1

©2012-2024 LAB GAGES