High speed roundness measurement systems for the bearings industry

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr Li

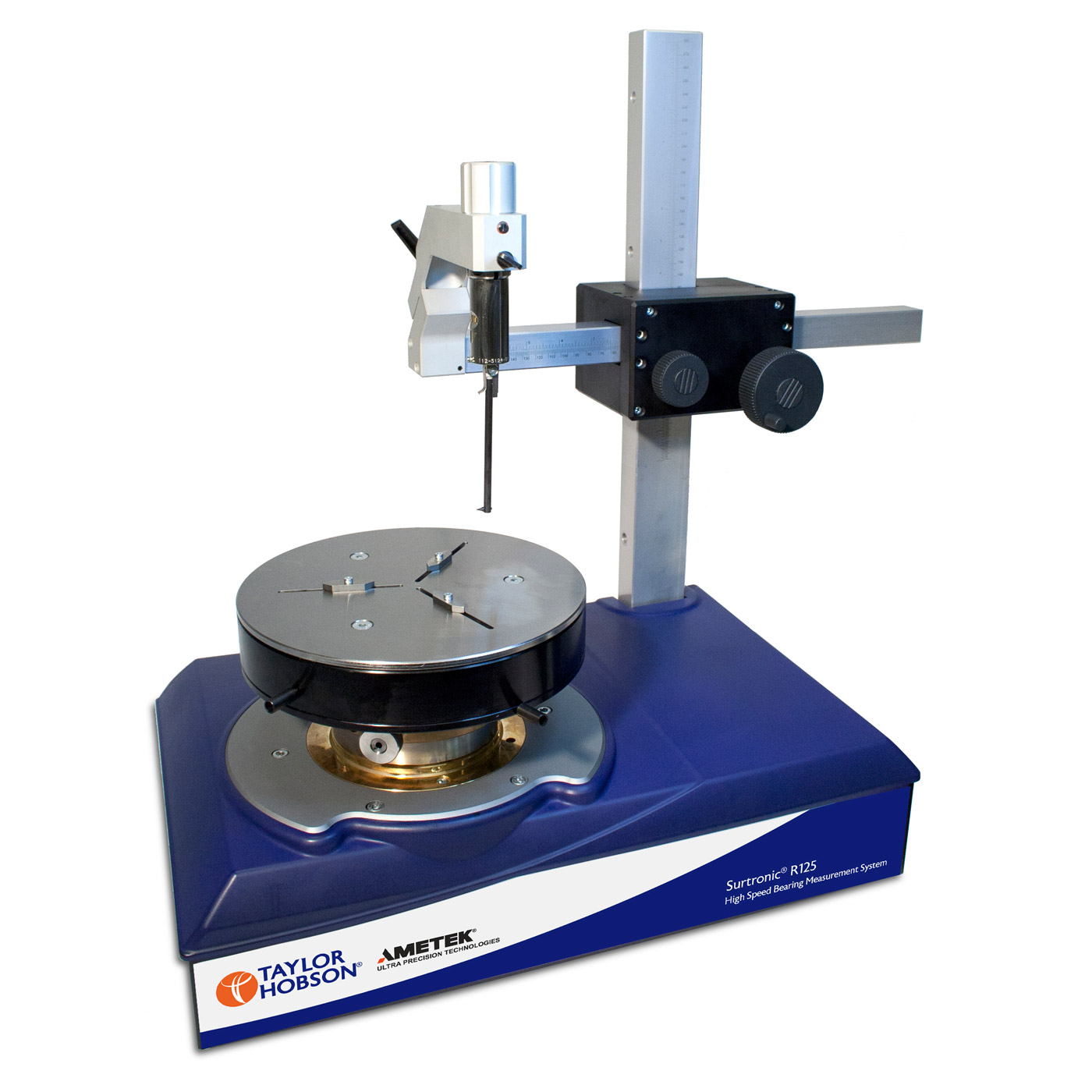

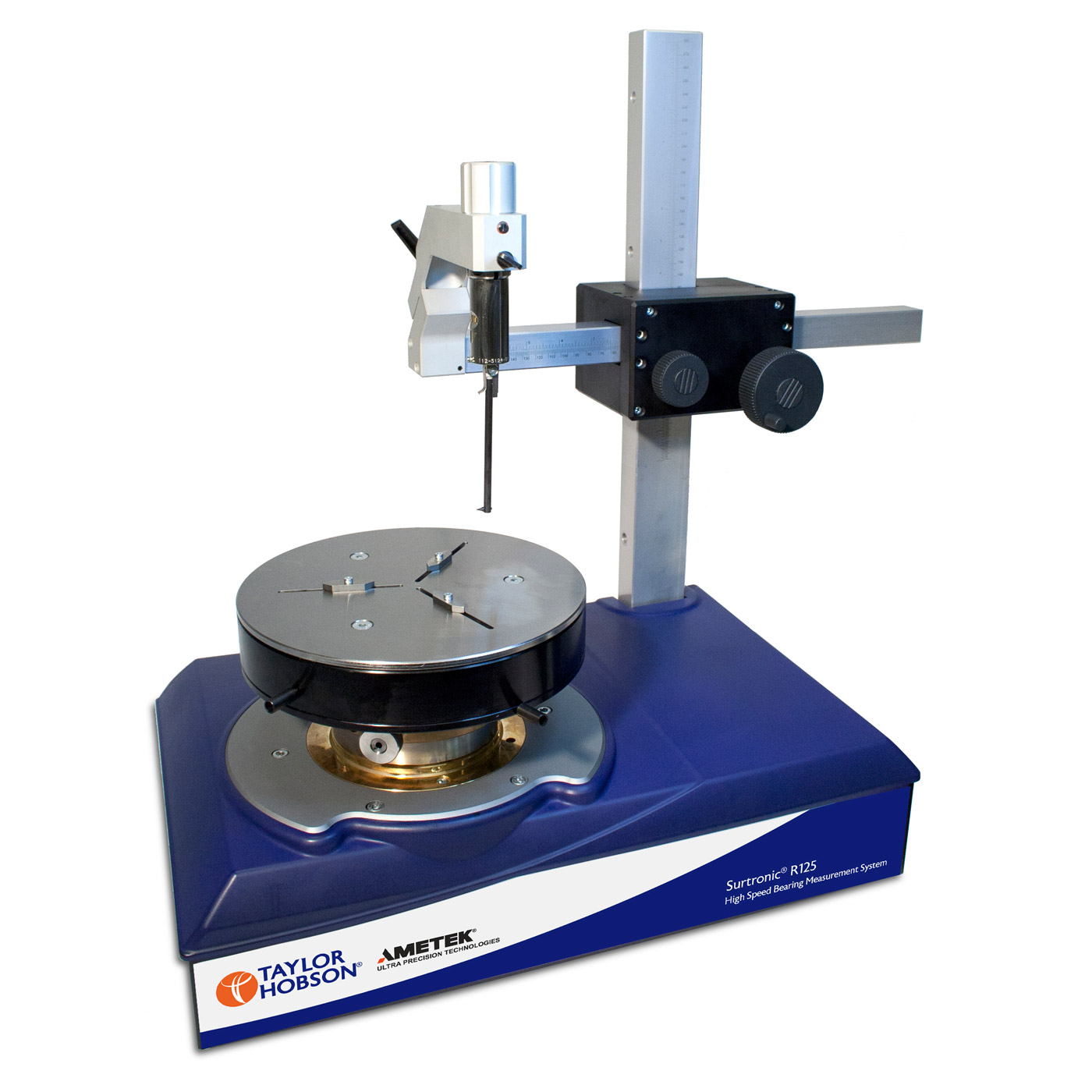

Surtronic R-100 Series

High speed roundness measurement systems for the bearings industry

|

Working closely with bearings manufacturers, Taylor Hobson has focussed on the key attributes that are most important for quality control in today’s precision industries. |

|

Speed (3 parts/minute including set-up) The most important benefit these systems offer is speed. In precision industries as manufacturing volumes increase all too often the bottleneck is metrology. High measurement throughput systems ensure higher sampling rates are achieved while also supporting increased manufacturing volumes. Precision (±25 nm spindle accuracy) Although many times faster than traditional benchtop roundness systems there is no loss of precision or accuracy. Full ISO compliant measurements can be taken with ±25 nm accuracy and 6 nm gauge resolution. Robustness (suitable for 24/7 operation) All systems are designed for constant 24 hour, 7 days a week use in demanding shop floor environments; manufactured using only the most durable and hard wearing materials. Ease of use (touchscreen software) The X-sight touch screen software platform with intuitive navigation make the Surtronic® roundness system as easy to use as a SatNav or SmartPhone with everything you need at your fingertips. |

|

| World’s highest throughput roundness system… | |

|

● Increase manufacturing output ● Reduce part scrappage |

● Ensure part traceability ● Improve ‘right first time’ |

|

What can it measure? The Surtronic® R-series instruments are ideally suited to measuring high volume production parts across a wide variety of industries including: Bearings – Races, Balls, Needles and Rollers |

|

|

|

Gauge orientation Using Taylor Hobson’s gauge orientation with its robust locking mechanism changing orientation from roundness to flatness or internal to external only takes a few seconds. Accurate gauging All systems incorporate Taylor Hobson’s accurate and reliable Talymin gauge technology, delivering 6 nm resolution. Rapid centreTM Rapid Centre avoids valuable cycle time being lost on manual part centring. On most parts precision results are achieved following a very simple and fast loading procedure. Now roundness measurements can be made in less than 30 seconds including part loading, centring, measurement, analysis and results display! |

|

|

Accessories and standards A full range of accessories and standards are available to support the instrument. These include Magnetic chuck, Rapid Centre fixture, Glass hemisphere, Calibration set, Precision test cylinder, Cresting standard, Stylus kit, Flick standard (20 µm or 300 µm) and replacement air filter modules. |

|

Surtronic R Series (more than a measurement instrument.../...a new measurement concept) |

|

|

Easy to use sofeware ●Developed in collaboration with key bearings, automotive and precision engineering companies ●Large colour display, easy viewing of results ●Touch screen operation means every feature at your fingertips ●Easy analysis setup with button recall ●Advanced analysis packages for bearings and automotive applications |

|

|

|

Applications--Bearing components |

|

|

|

|

|

|

Ball bearings |

Balls |

Needle and roller bearings |

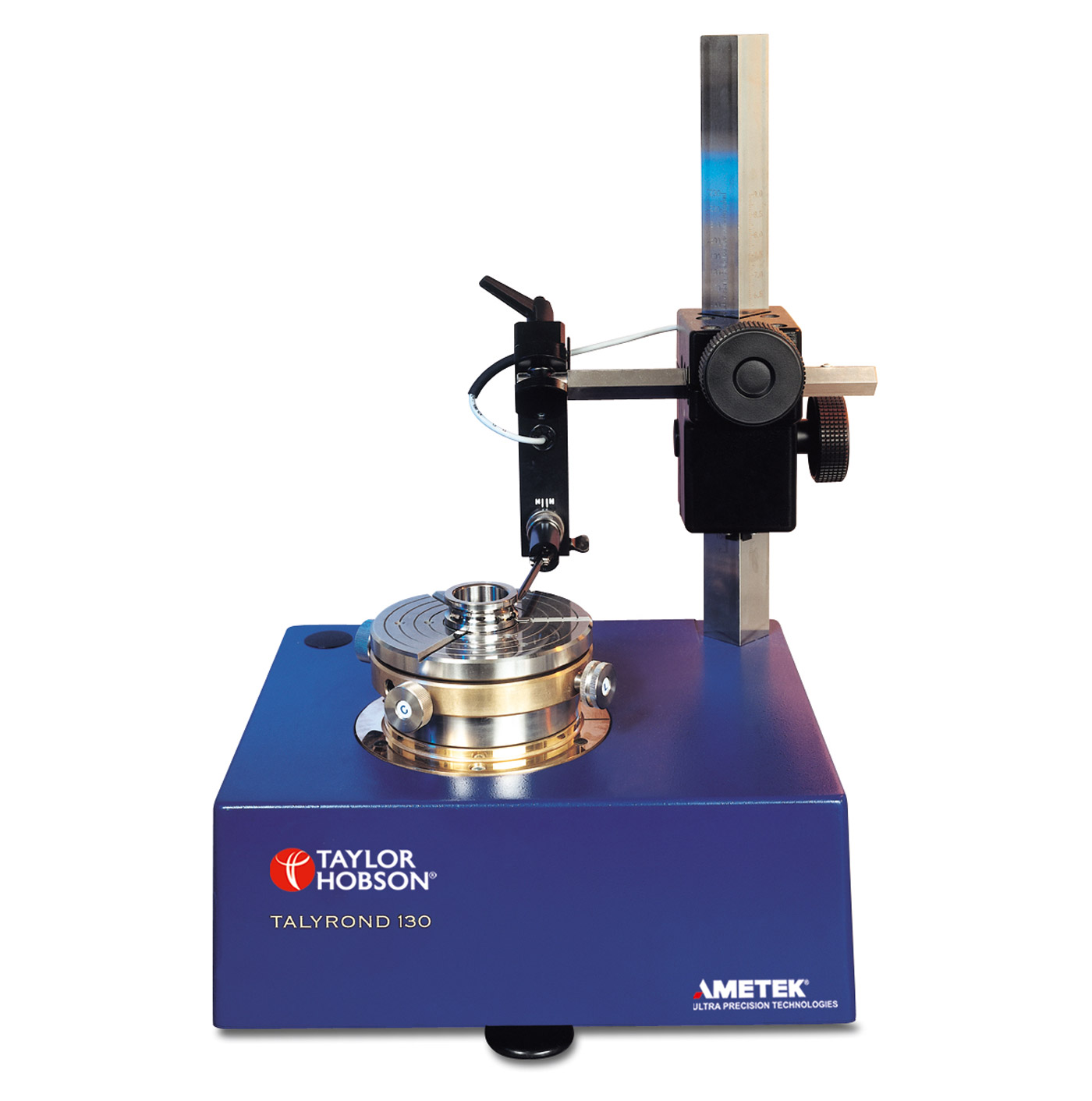

Talyrond 130 Economical High Precision Roundness Measuring Instrument

Talyrond 130 Economical High Precision Roundness Measuring Instrument Talyrond 131C Efficient Cylindricity Measuring Instrument

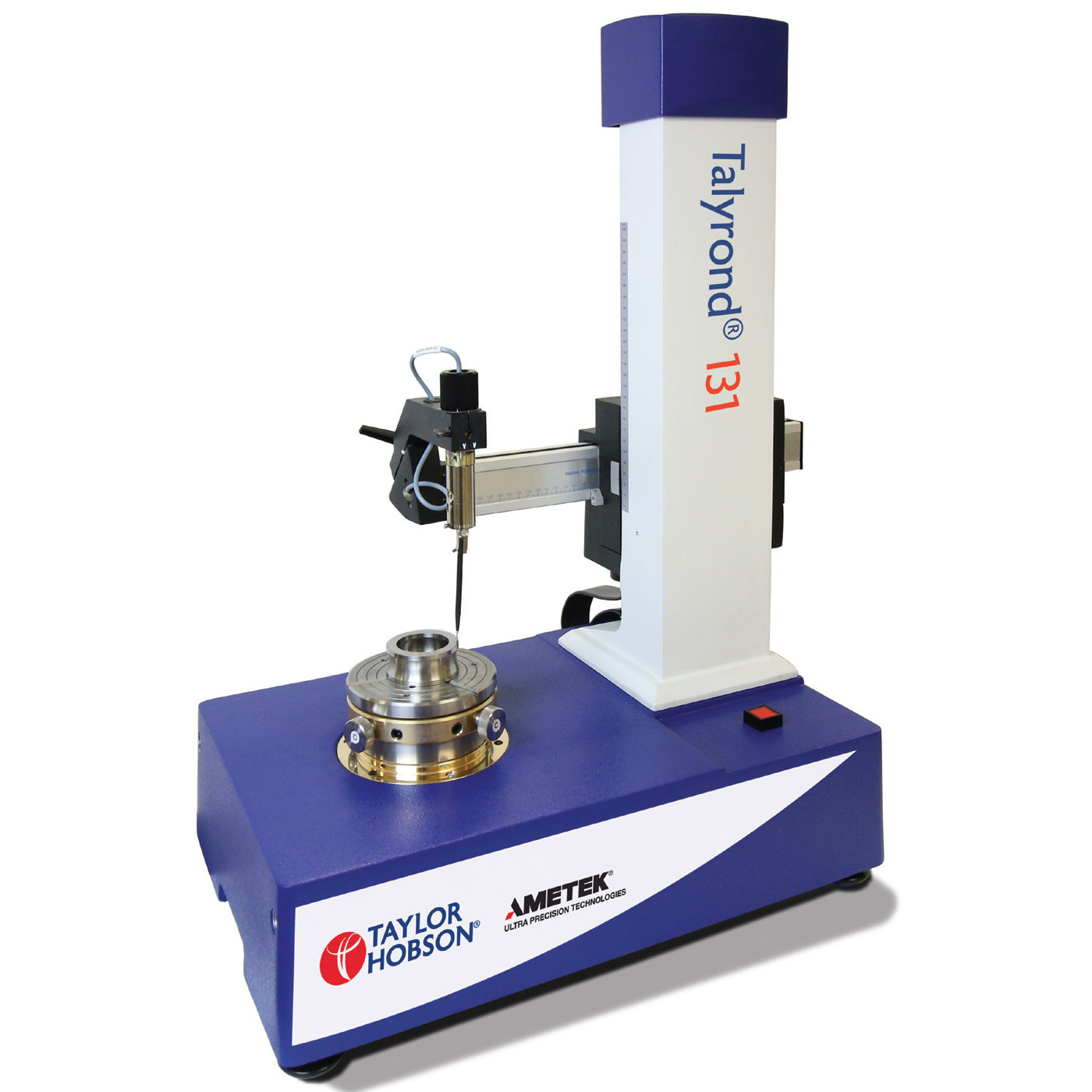

Talyrond 131C Efficient Cylindricity Measuring Instrument Talyrond 565 Roundness Measuring Instrument

Talyrond 565 Roundness Measuring Instrument Talyrond 585H series high precision roundness measuring instrument

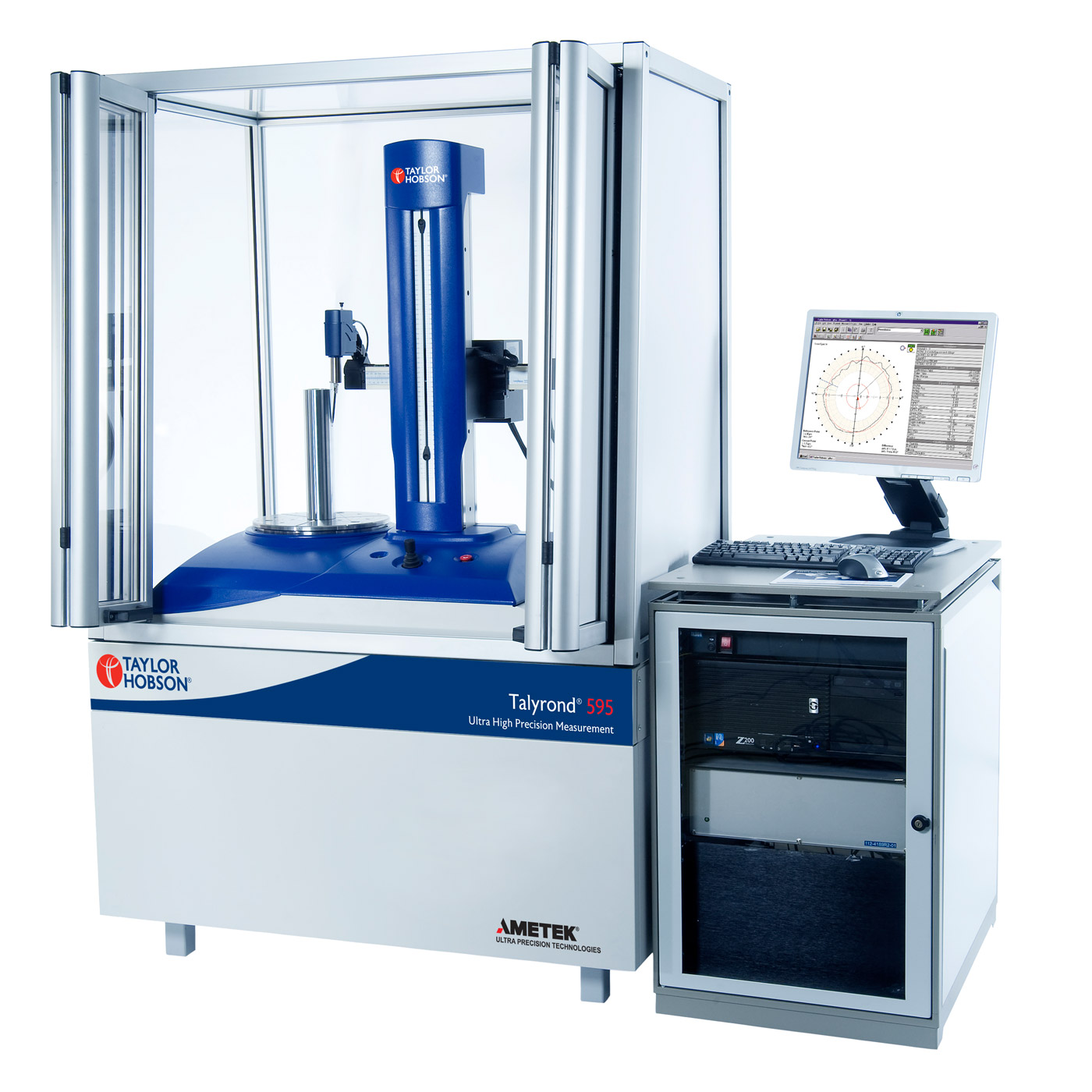

Talyrond 585H series high precision roundness measuring instrument Talyrond 595 High Precision Roundness Measuring Instrument

Talyrond 595 High Precision Roundness Measuring Instrument Talyrond 400H Series Cylindrometer

Talyrond 400H Series Cylindrometer TalyMaster Multi-Part High Precision Roundness Tester

TalyMaster Multi-Part High Precision Roundness Tester Talyrond 450 Large Roundness Measuring Instrument

Talyrond 450 Large Roundness Measuring Instrument Talyrond 565-585XL large roundness measuring instrument

Talyrond 565-585XL large roundness measuring instrument Surtronic R100 Series

Surtronic R100 Series

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

沪公网安备 31011502000213号

沪ICP备12021537号-1

©2012-2024 LAB GAGES

沪ICP备12021537号-1

©2012-2024 LAB GAGES