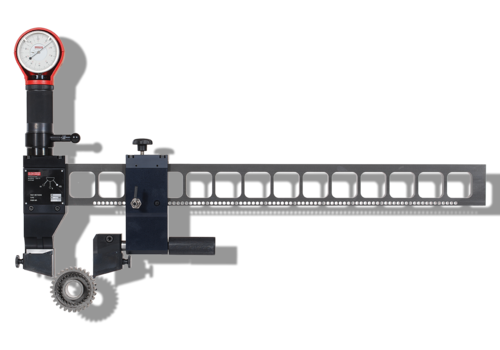

The only portable gear Rockwell hardness tester in the world that directly tests Rockwell hardness on gear surface.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr LiEMCOTEST portable hardness tester from Austria has more than 60 years of experience and has been widely used in various industries for decades. The core component is a reliable ballast system-spring sleeve system. The measured value is displayed on the top indicator.

|

|

✍ The only portable gear Rockwell hardness tester in the world that directly tests Rockwell hardness.

✍ Use it like a common normal caliper, clamp a few teeth, and measure the tooth surface hardness of the gear pitch circle position.

✍ The test range is wide. The test range includes the modulus of 2 to 35, the common normal length is less than 1500mm, and it covers most industrial gears.

✍ The operation is simple and easy to use. The test can be completed by just a few pushes of the afterburner. The average batch measurement time is less than 10 seconds.

✍ The real Rockwell hardness test method is adopted, and the test results are true, reliable and accurate.

✍ The instrument can be used to test various common gears such as internal teeth, external teeth, straight teeth, helical teeth, bevel teeth, spiral teeth and so on.

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

沪公网安备 31011502000213号

沪ICP备12021537号-1

©2012-2024 LAB GAGES

沪ICP备12021537号-1

©2012-2024 LAB GAGES